Popular Keywords

- About Us

-

Research Report

Research Directory

Semiconductors

LED

Consumer Electronics

Emerging Technologies

- Selected Topics

- Membership

- Price Trends

- Press Center

- News

- Events

- Contact Us

- AI Agent

About TrendForce News

TrendForce News operates independently from our research team, curating key semiconductor and tech updates to support timely, informed decisions.

- Home

- News

[News] SK hynix May Stick With MR-MUF for HBM4 16-High amid Fluxless Bonding Evaluation

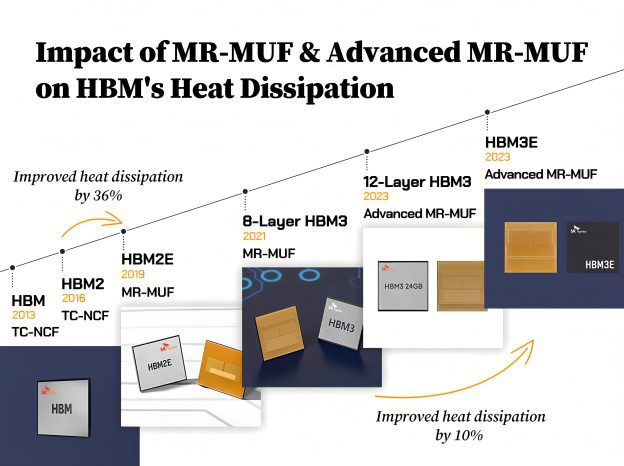

SK hynix is expected to continue using its MR-MUF process for HBM4 16-high products. According to DealSite, the company evaluated adopting fluxless bonding for HBM4 16-high but ultimately opted to retain its existing advanced MR-MUF process, concluding that the technology remains premature given performance and cost considerations.

Sources cited by the report say SK hynix launched full-scale evaluations in the fourth quarter of last year to introduce fluxless bonding for HBM4 16-high, with the aim of applying it across the entire production volume. However, the evaluation results failed to meet expectations.

The report further points out that although HBM4 16-high raises technical difficulty due to tighter stacking constraints, industry consensus is that advanced MR-MUF can adequately support the design. SK hynix has also confirmed in overseas investor briefings, the report adds, that it will maintain its current process through HBM4 and HBM4E 16-high products. According to EE Times, the company unveiled a 16-high HBM4 at CES 2026, using its proprietary MR-MUF technology to thin individual DRAM wafers to just 30 µm, enabling the stack to meet JEDEC’s strict 775 µm height limit.

Preparing for Post-20-Layer Stacks: Fluxless Bonding as a Bridge

However, the report notes that once stack heights exceed 20 layers, SK hynix believes adopting next-generation technologies will become unavoidable. This assessment led the company to evaluate fluxless bonding at an early stage, as it is viewed as a transitional step toward hybrid bonding. As the report explains, fluxless bonding removes the use of flux while remaining within the MR-MUF process family, which SK hynix sees as lowering the burden of process transition relative to competitors.

Meanwhile, industry observers have suggested that SK hynix’s recent order of TC bonders from ASMPT for HBM4 may be intended to support research into fluxless bonding. In November last year, the company ordered seven tools from ASMPT instead of sourcing from its long-time top TC bonder supplier, Hanmi Semiconductor. However, a source familiar with SK hynix said that the order appears unrelated to fluxless bonding, noting that the company merely placed orders for existing tools whose supply had already been decided, rather than equipment specifically tied to fluxless processes.

The report also notes that the approaching expiration of SK hynix’s exclusive MR-MUF materials agreement with Namics is influencing its strategy. The company plans to retain its existing process for HBM4 and HBM4E 12- and 16-high products, while a transition to hybrid bonding is seen as the preferred next step, albeit with potentially delayed timing.

Read more

- [News] SK hynix Reportedly Places HBM4 TC Bonder Order With ASMPT Amid Hanmi–Hanwha Patent Clash

- [News] SK hynix Reportedly Accelerates Hybrid Bonding for 300-Layer V10 NAND, Eying 2027 Mass Production

(Photo credit: SK hynix)