Popular Keywords

- About Us

-

Research Report

Research Directory

Semiconductors

LED

Consumer Electronics

Emerging Technologies

- Selected Topics

- Membership

- Price Trends

- Press Center

- News

- Events

- Contact Us

- AI Agent

About TrendForce News

TrendForce News operates independently from our research team, curating key semiconductor and tech updates to support timely, informed decisions.

- Home

- News

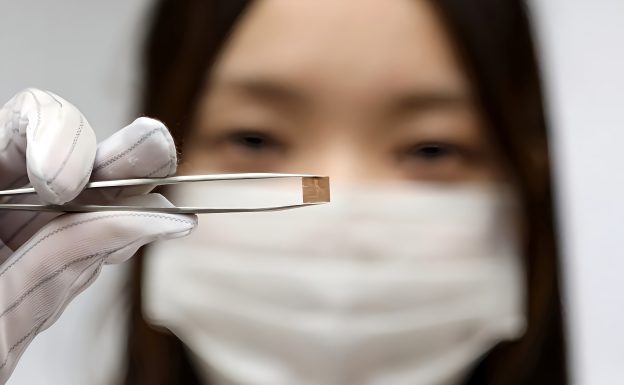

[News] LG Innotek Unveils Copper Post Substrate Tech for Slimmer Smartphones

LG Innotek announced that it has successfully developed the world’s first copper post (Cu-Post) technology and applied it to the mass production of mobile semiconductor substrates, according to its press release. As noted by TechNews, citing Tom’s Hardware, LG Innotek’s Cu-Post replaces the traditional use of solder balls to connect the chip substrate to the mainboard, enabling smartphones to become thinner and more high-performance.

The report notes that the core of this technology lies in first placing copper posts on the substrate, then positioning solder balls on top of the posts. Compared to the conventional method of directly attaching solder balls, this approach reduces the spacing between them by approximately 20%, resulting in higher packaging density.

In addition, the report highlights that copper has a much higher melting point than solder, allowing it to maintain structural stability during high-temperature processes and prevent solder ball deformation or displacement during bonding. Moreover, copper’s thermal conductivity is about seven times greater than that of conventional solder, enabling faster heat dissipation.

As stated in its press release, LG Innotek has secured around 40 patents related to its Cu-Post technology and plans to apply it to RF-SiP and FC-CSP (Flip Chip–Chip Scale Package) substrates.

The company also aims to grow its semiconductor components business by focusing on high-value-added products such as FC-BGA and RF-SiP substrates, along with vehicle AP modules, with a goal of reaching over $2.2 billion in annual revenue by 2030, according to the press release.

However, as TechNews points out, while LG Innotek’s copper post packaging solution has the potential to reshape the landscape of the semiconductor packaging, the process presents significant challenges. TechNews notes that microstructure manufacturing requires extremely high precision, making chip integration and production yield difficult to manage. Additionally, the higher cost of copper compared to solder makes return on investment a key issue that the industry must carefully assess.

Read more

- [News] LG Innotek Reportedly Deepens Robotics Push with Camera Module Supply to Figure AI

- [News] Absolics Reportedly Ramps Up Glass Substrate Output, Mass Production Expected by Year-End

(Photo credit: LG Innotek)