Popular Keywords

- About Us

-

Research Report

Research Directory

Semiconductors

LED

Consumer Electronics

Emerging Technologies

- Selected Topics

- Membership

- Price Trends

- Press Center

- News

- Events

- Contact Us

- AI Agent

About TrendForce News

TrendForce News operates independently from our research team, curating key semiconductor and tech updates to support timely, informed decisions.

- Home

- News

[News] Samsung Reportedly Sets March EUV Trials at Taylor Fab Ahead of Tesla Chip Production

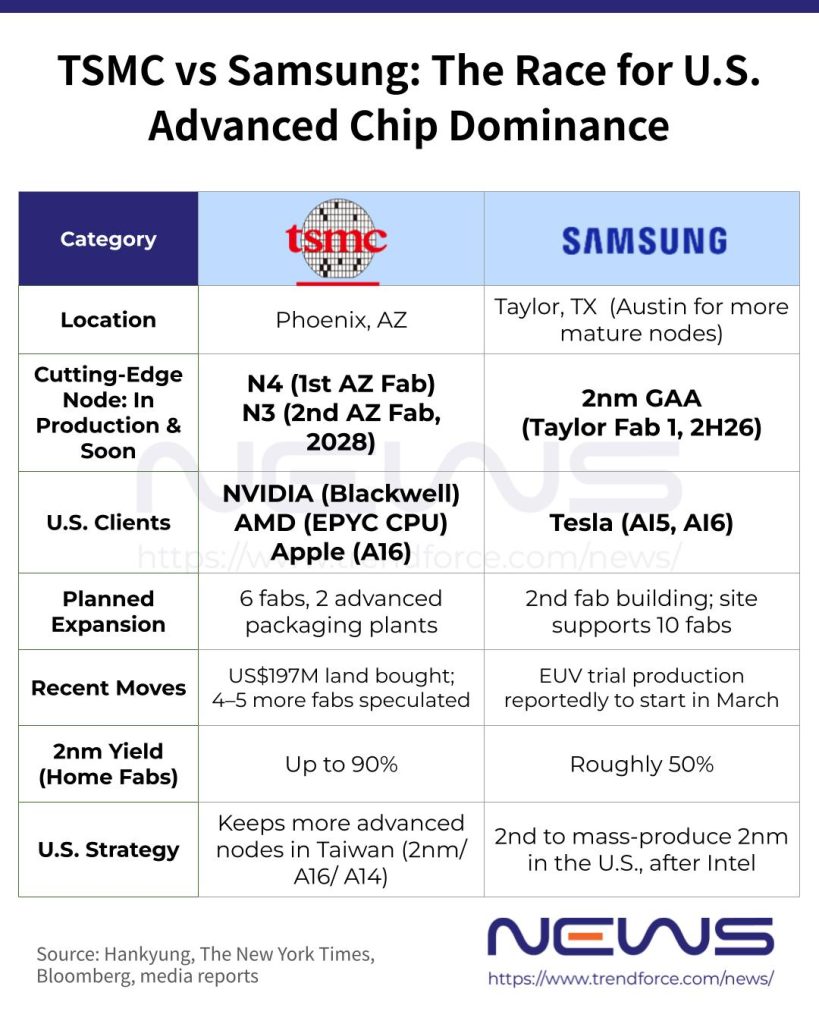

While TSMC signals plans to accelerate its Arizona expansion amid rumors of five additional fabs, Samsung is also pushing ahead at its Taylor site. According to Hankyung, trial operations of extreme ultraviolet (EUV) lithography equipment at Taylor Fab 1 will start this March, setting the stage for mass production of Tesla’s AI5 and AI6 autonomous driving chips.

As per Hankyung, Samsung plans to sequentially install etching and deposition tools, with full-scale production scheduled for the second half of 2026. The company is expected to soon apply for a Temporary Certificate of Occupancy (TCO) from Texas authorities, allowing the fab to begin operations before formal completion.

An on-site contractor told Hankyung that roughly 7,000 workers are now on-site daily, with about 1,000 already in the six-story office building as the project nears completion. The transformation is striking compared with a year ago, when most cranes still loomed over the site and parking lots sat mostly empty, the report notes.

It is worth noting that Samsung’s Taylor fab spans roughly 4.85 million square meters—larger than its Pyeongtaek and Hwaseong sites combined, Hankyung reports. The company has secured enough space to build up to 10 additional fabs, highlighting the site’s massive potential for future expansion, the report adds.

Meanwhile, major foundry rival TSMC has intensified its U.S. expansion with a US$197 million land purchase in Arizona for a future gigafab. The New York Times and Bloomberg reported that TSMC might be planning to build at least four or five additional fabs in the state, on top of the six factories and two advanced packaging facilities it has already committed.

2nm Yield Challenges Persist

According to Hankyung, Samsung’s first fab at Taylor is set to begin production in the second half of the year, and the report notes that operations at Taylor Fab 2—currently in the early stages of construction—could start earlier if Samsung secures more customers.

The Taylor site, initially planned for 4nm production, now targets 50,000 2nm wafers, taking advantage of TSMC’s hesitation to bring its most advanced nodes to the U.S., Hankyung reports. Meanwhile, TSMC’s first Arizona fab began N4 production in Q4 2024, while its second fab, slated for 2028, is set to focus on the N3 process.

However, Hankyung also highlights concerns over Samsung’s 2nm yields. TSMC, which began 2nm mass production at its Taiwan fabs in late 2025, reportedly achieved yields of 70–90 percent, while Samsung’s 2nm pilot line has yet to reach comparable levels. Still, G-Enews reports that Samsung has now hit a 50% yield and launched full-scale promotion of its second-generation 2nm technology, SF2P.

Read more

- [News] Samsung Chairman Reportedly Meets Musk, Granting Tesla CEO Dedicated Workspace at Taylor Fab

- [News] Samsung Reportedly Speeds Up U.S. Hiring as Tesla Prepares for AI5 Production

(Photo credit: Samsung)