Popular Keywords

- About Us

-

Research Report

Research Directory

Semiconductors

LED

Consumer Electronics

Emerging Technologies

- Selected Topics

- Membership

- Price Trends

- Press Center

- News

- Events

- Contact Us

- AI Agent

About TrendForce News

TrendForce News operates independently from our research team, curating key semiconductor and tech updates to support timely, informed decisions.

- Home

- News

[News] Chinese Research Team Achieved New Advances in Lithographic Manufacturing Technology

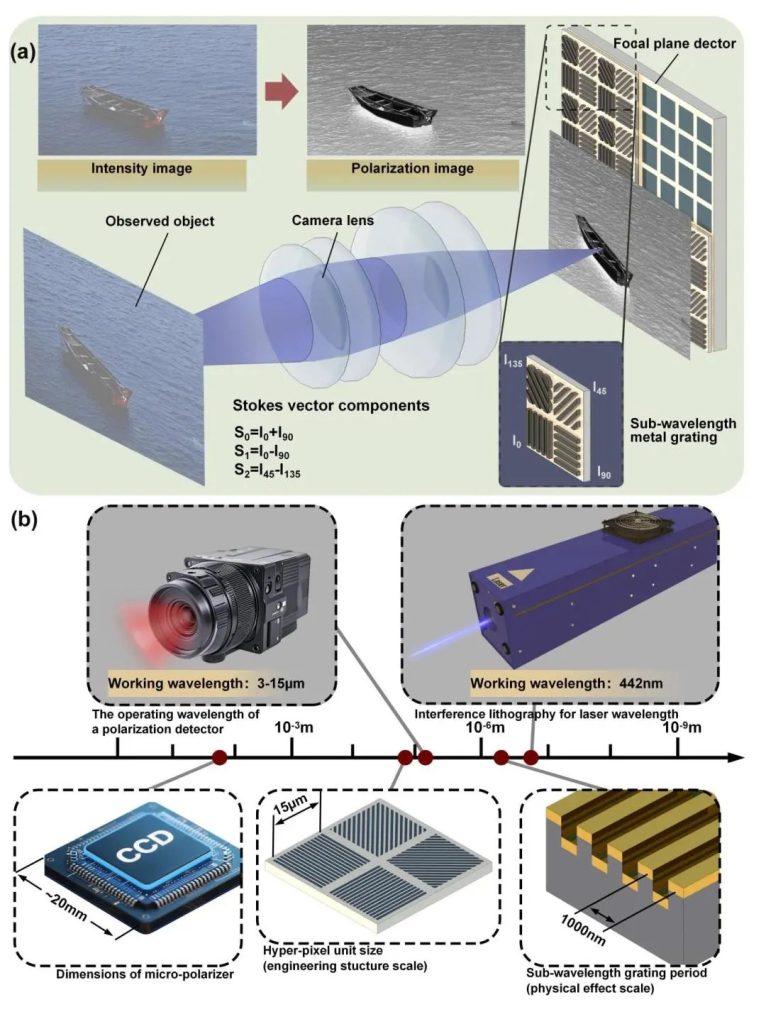

Focal plane arrays (FPAs) have attracted widespread attention in the field of polarization imaging due to their high level of integration, robustness, and strong dynamic adaptability. The key to fabricating FPAs lies in producing arrayed anisotropic subwavelength gratings. Conventional techniques such as nanoimprint lithography and mask-based photolithography rely on high-precision templates, limiting flexibility, while direct-write methods like electron-beam lithography struggle to meet the efficiency requirements of large-area fabrication.

Recently, a research team led by Associate Professor Li Xinghui at Tsinghua Shenzhen International Graduate School has made new progress in the lithographic fabrication of focal-plane superpixel arrays, providing a novel solution for the fabrication of key components in mid-infrared polarization imaging systems.

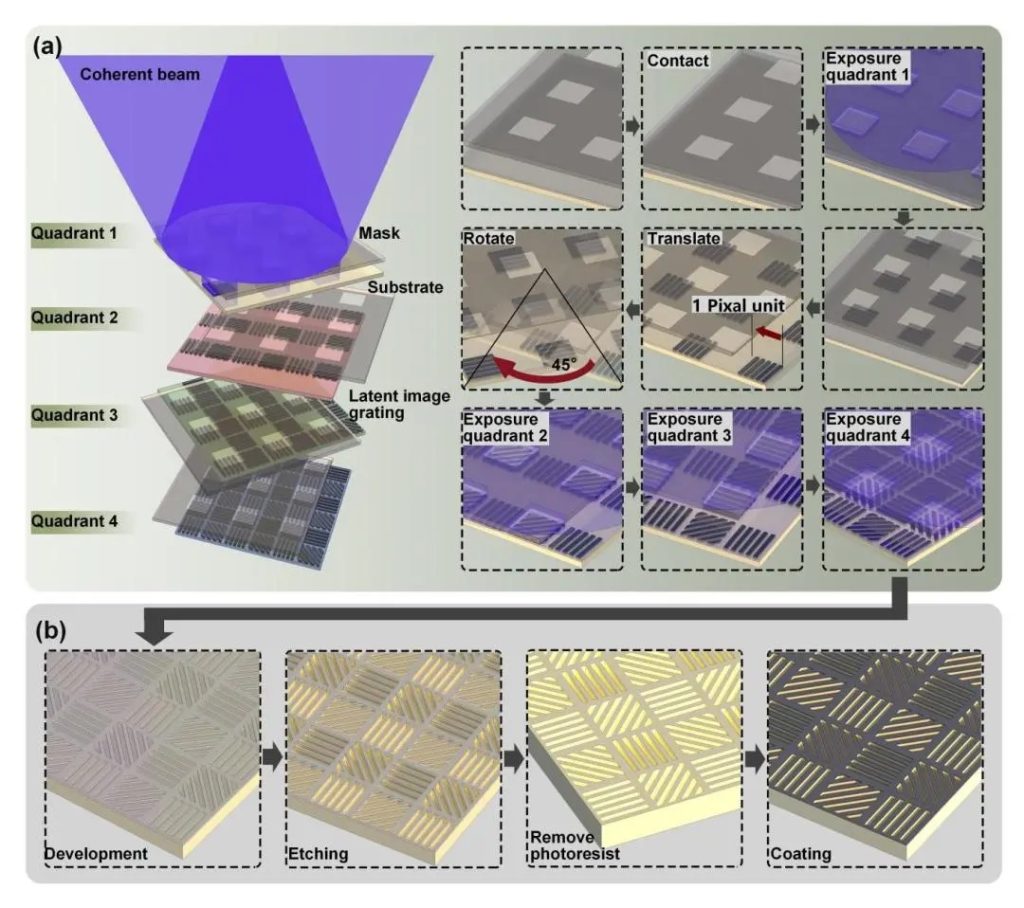

For mid-infrared polarization imaging applications, the team proposed a single-cycle contact–interference hybrid lithography technique. This approach uses a window mask that does not contain fine grating stripe structures to segment and trim the interference fringes generated by interference lithography. A four-step exposure process was employed to generate latent fringe patterns of 34μm × 34μm superpixel arrays over an area of 20mm × 20mm. Each superpixel array contains four gratings with different orientations and an 800 nm period, and the patterns are transferred through a single cycle of development, etching, and coating processes.

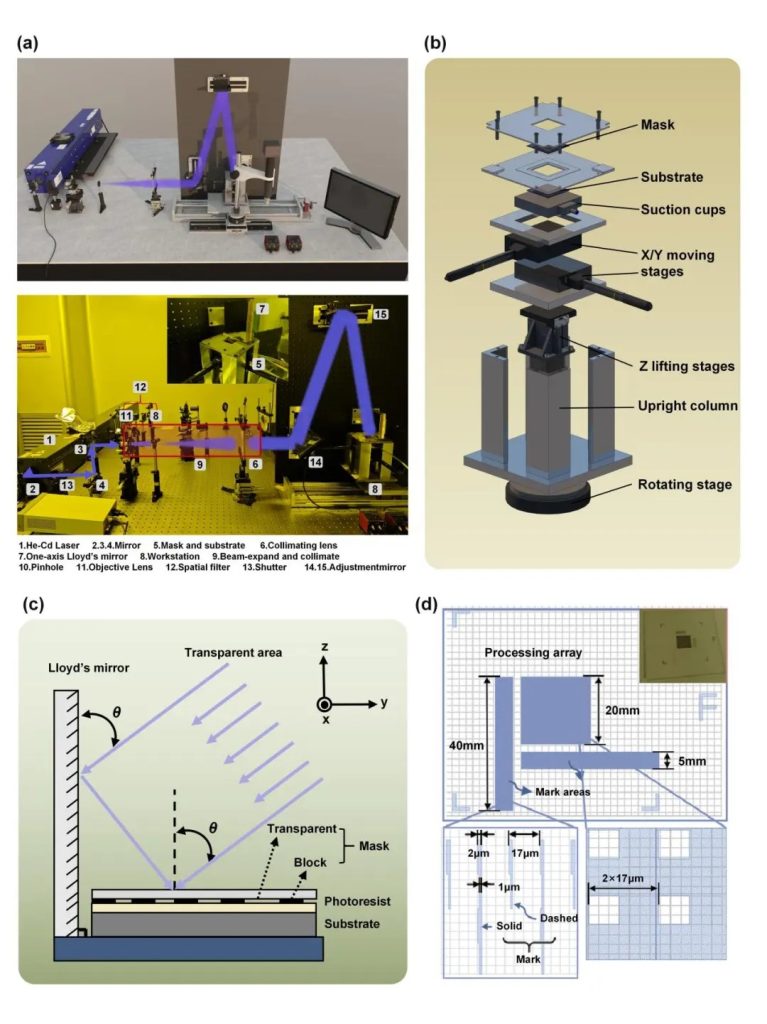

Within this technical route, to reduce the impact of the gap between the mask and the substrate on interference fringe quality, the research team used finite-difference time-domain (FDTD) simulations to analyze the effects of gap size and gap-filling media on the interference fringes. Glycerol was selected as a refractive-index-matching material to fill the gap, and a lifting stage was used to control the gap within 10μm, which significantly suppresses adverse effects on fringe quality.

To address overlay alignment issues during stepwise exposure, the team developed a sub-micrometer-precision alignment scheme based on microscopic imaging technology and built a dedicated alignment observation platform. This method employs dual-region periodic stripe markers on the mask to achieve vertex-based alignment between the mask and the substrate.

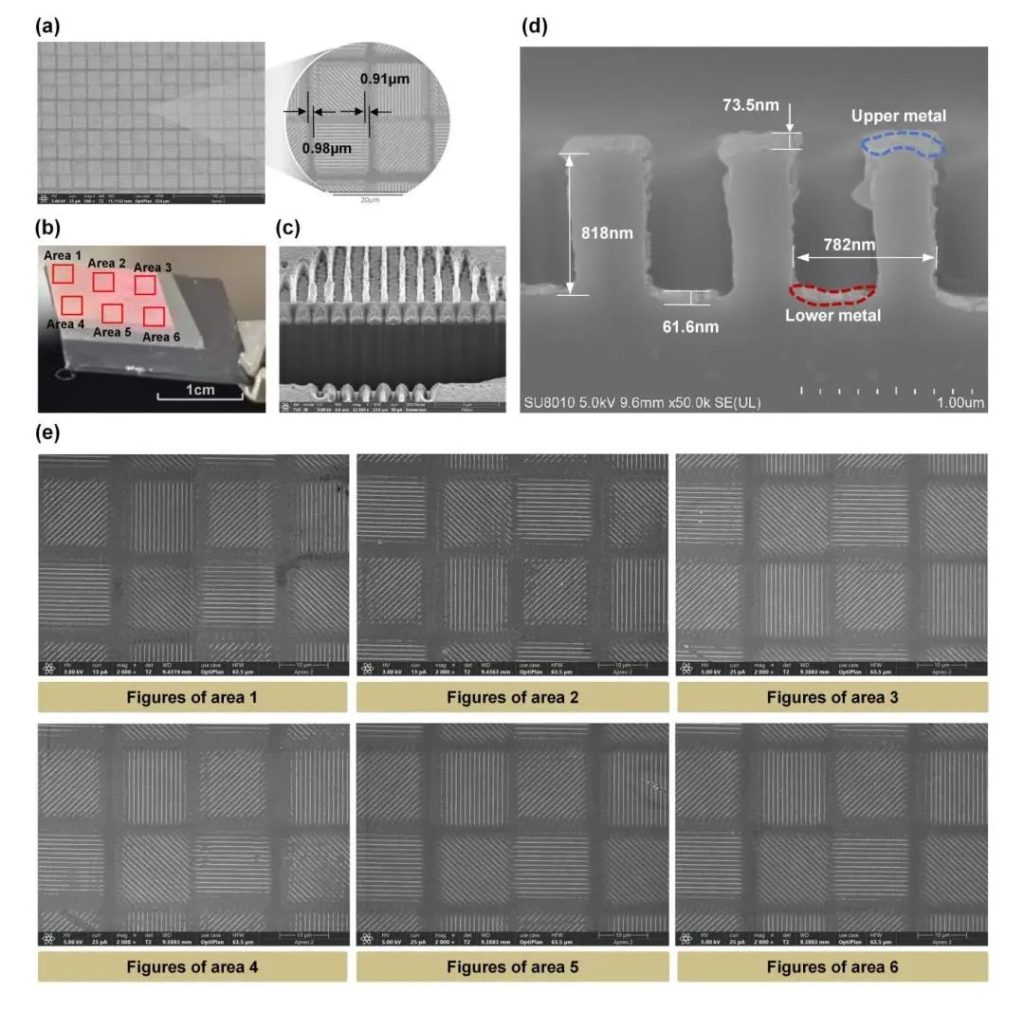

The researchers also constructed a customized microscope objective to precisely observe the alignment between specially designed periodic line markers on the mask and the vertex patterns on the grating substrate. Based on this system, the team successfully achieved sub-micrometer overlay alignment in stepwise lithography, effectively avoiding crosstalk between different grating regions. The fabricated samples were subjected to systematic surface morphology characterization and optical performance testing.

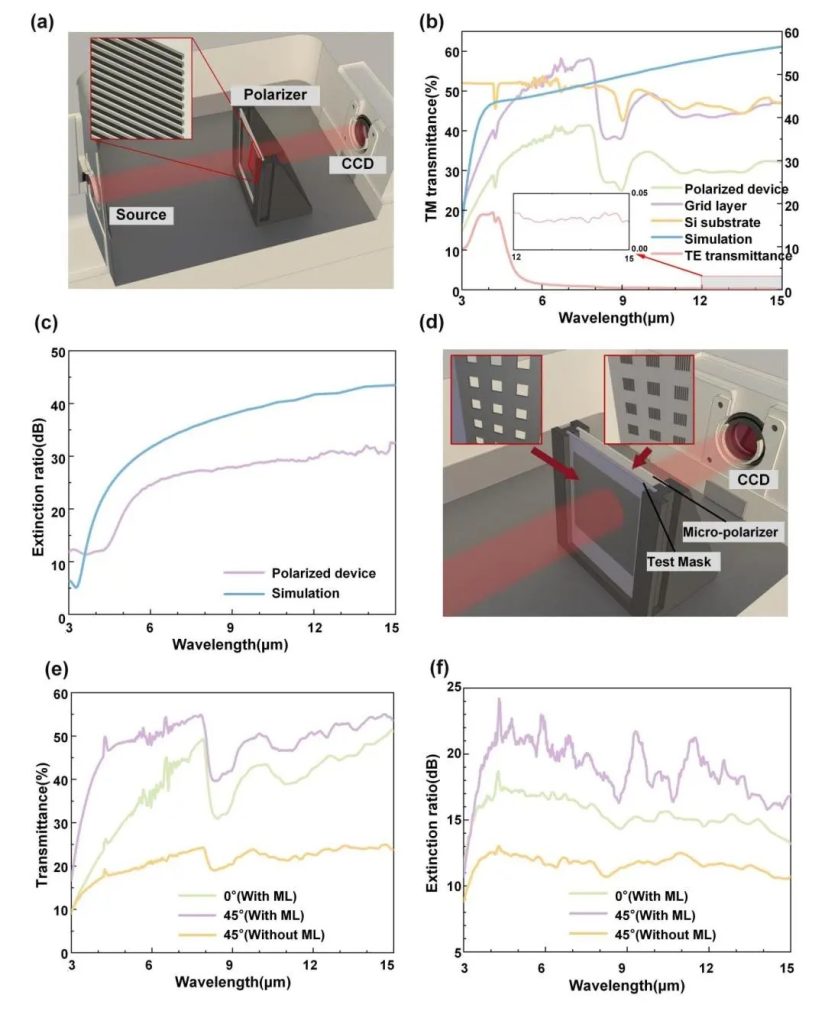

Scanning electron microscopy (SEM) was used to characterize six regions on the sample surface, all of which exhibited good fringe quality and overlay alignment accuracy. A Fourier-transform infrared (FTIR) spectrometer was employed to measure optical transmittance and polarization extinction ratio. The results show that, in the 3μm–15μm mid-infrared band, the maximum transmittance for TM-polarized light of any subpixel reached 50%, with a polarization extinction ratio of 20 dB.

The proposed hybrid lithography technique demonstrates significant advantages in fabricating medium-complexity, multi-period structures, such as focal-plane subwavelength arrays, offering strong engineering application potential and important research value. The results were published under the title “Single-Cycle Contact–Interference Hybrid Lithography for Scalable Manufacturing of Arrayed Quadrant Micro-Polarizer Structures” in the top-tier engineering journal Extreme Manufacturing.

Figure 1: Structure and operating principle of the focal plane array

Figure 2: Fabrication process of hybrid lithography

Figure 3 | Hybrid lithography system proposed in this work:

(a) laser interference lithography system;

(b) substrate–mask pose adjustment platform;

(c) wavefront-segmented interference lithography system and substrate–mask stage;

(d) mask design with alignment capability

Figure 4: Characterization and optical testing of the focal plane grating array

(Photo credit: FREEPIK)