Popular Keywords

- About Us

-

Research Report

Research Directory

Semiconductors

LED

Consumer Electronics

Emerging Technologies

- Selected Topics

- Membership

- Price Trends

- Press Center

- News

- Events

- Contact Us

- AI Agent

About TrendForce News

TrendForce News operates independently from our research team, curating key semiconductor and tech updates to support timely, informed decisions.

- Home

- News

[News] South Korea to Double SiC Self-Sufficiency to 20% by 2030 Amid Chip Independence Push

According to Newsis, the South Korean government said it will double the nation’s technology self-sufficiency rate in silicon carbide (SiC) power semiconductors, raising it from the current 10% to 20% in 2030.

The report points out that SiC power semiconductors are gaining traction in sectors such as electric vehicles, renewable energy, and data centers. However, about 90% of the market is concentrated in just a few countries, including Switzerland, the U.S., and Germany. To address this, the South Korean government has resolved to boost domestic self-sufficiency in SiC. It will invest 90.2 billion won in state funding by 2028, including 24.9 billion won next year, as the report notes.

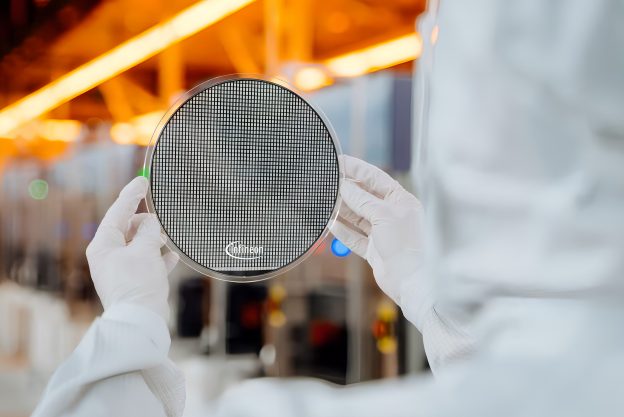

According to TrendForce, Wolfspeed held its lead as the top SiC substrate supplier in 2024 with a 33.7% market share, despite ongoing operational challenges. The company remains a dominant force in the SiC materials market and continues to spearhead the industry’s shift to 8-inch wafers. Meanwhile, Chinese vendors TanKeBlue and SICC have quickly risen as major players, securing 17.3% and 17.1% shares, ranking second and third, respectively.

South Korea Sets Roadmap for Graphene Commercialization

In addition to SiC, the South Korean government will step up efforts to advance graphene commercialization. Business Korea notes that Korea has already secured original technology through significant investment, but commercialization remains at an early stage, with prototypes mainly supplied for applications such as display thermal management.

By 2027, South Korean government aims to establish infrastructure for graphene commercialization, with plans to enter the energy storage material market by 2030 and the sensor material market by 2035, as Newsis indicates.

Dubbed a “wonder material,” graphene owes its reputation to the extraordinary qualities of its nanoscale structure. It offers outstanding thermal and electrical conductivity, notable elasticity, and, according to the American Chemical Society, is both the thinnest and strongest material available—100,000 times thinner than paper and 200 times stronger than steel, as highlighted by The Korea Economic Daily. Potential industrial applications span electronic devices, batteries, and electric vehicles (EVs), the report adds.

Read more

- Global SiC Substrate Revenue Declines 9% in 2024; Long-Term Demand Remains Strong as 8-Inch Roadmap Gains Momentum, Says TrendForce

- [News] TSMC Eyes Breakthroughs in SiC Thermal Management

(Photo credit: Infineon)