Popular Keywords

- About Us

-

Research Report

Research Directory

Semiconductors

LED

Consumer Electronics

Emerging Technologies

- Selected Topics

- Membership

- Price Trends

- Press Center

- News

- Events

- Contact Us

- AI Agent

About TrendForce News

TrendForce News operates independently from our research team, curating key semiconductor and tech updates to support timely, informed decisions.

- Home

- News

[News] SiC Raw Materials See a Price Increase While 6-Inch Substrate Kicks off a Price War

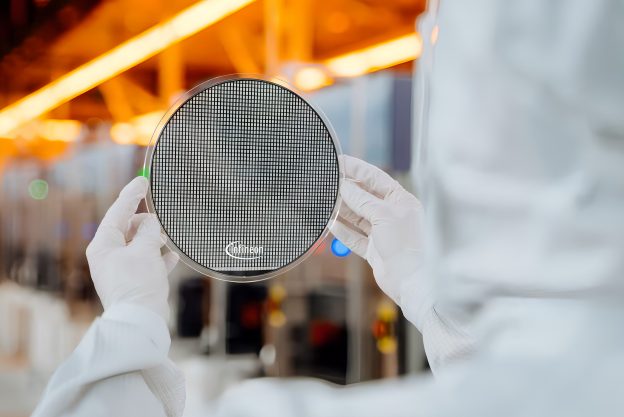

As of November 2025, the silicon carbide (SiC) market is undergoing a critical phase of value re-evaluation and structural divergence. On the pricing front, low-end bulk SiC materials are experiencing price increase due to runaway costs, while mainstream 6-inch SiC substrates continue to plunge amid oversupply. On the application side, however, SiC’s exceptional thermal conductivity positions it as a strategic material for AI chipset heat dissipation in NVIDIA’s Rubin platform and TSMC’s advanced packaging—signaling a second wave of high-value growth driven by HPC applications.

SiC Pricing Trends: Upward Pressure on Raw Materials, Intense Price Cuts in High-End Substrates

The SiC market is exhibiting a clear differentiation in pricing dynamics.

On one hand, the prices of bulk SiC materials—such as black and green SiC powders and grains—have been on the rise. According to pricing platforms including CIP Commodity Index and BaiInfo, bulk SiC traded at CNY 6,271 per metric ton over the past week, up 0.21% week-over-week.

This round of price increase is driven by three core factors: firm feedstock costs, expanding downstream demands, and supply adjustment linked to environmental inspections and capacity constrain, which together pass cost pressure onto the distribution chain, pushing baseline material prices higher.

On the other hand, 6-inch SiC wafer substrates used in power devices plunged into a fierce price war. The rapid capacity expansion by major global suppliers has led to excess supply, driving substrate prices sharply downward.

Industry sources indicate that prices fell below USD 500 per wafer from mid-2024 to Q4—more than a 20% decline. Entering 2025, the competitive pressure has continued, with mainstream quotes hovering around USD 400 or lower. Some suppliers are now offering prices close to cost, accelerating consolidation across the substrate market.

Application Spotlight: Structural Breakout from AI High-Performance Computing (HPC)

The adoption of SiC in high-performance computing (HPC) has emerged as the most decisive new growth driver as of late 2025. With GPU power levels soaring, traditional thermal materials can no longer meet dissipation requirements. SiC, with thermal conductivity reaching up to 500 W/m·K, has quickly become a core solution candidate.

Recent dynamics from global industry leaders highlight this shift:

- NVIDIA to Introduce SiC Substrate as Interposers in Rubin Platform:

NVIDIA is expected to adopt SiC technology in its 2025 Rubin platform, leveraging TSMC’s advanced CoWoS packaging process. The plan aims to upgrade the conventional silicon interposer to a silicon carbide one to handle the extreme thermal loads of next-generation AI accelerators.

- TSMC Advances 12-Inch SiC Carrier Board Ecosystem Building:

TSMC is working aggressively with suppliers to evaluate 12-inch single-crystal SiC as a high-performance thermal carrier, intended to replace traditional ceramic substrates in HPC systems. SICC—a leading SiC substrate provider—launched a full portfolio of 12-inch SiC substrates in Q1 2025 to support this emerging demand.

- Data Center Architecture Shift Boosting SiC Power Devices:

As NVIDIA drives global data centers toward 800V HVDC architectures, SiC power components are expected to see substantial demand growth, further expanding SiC’s role in AI server power delivery systems.

- Emerging Optical Applications: VR/AR/MR Headsets:

With a refractive index of 2.6–2.7—exceptionally higher than traditional optical glass—SiC shows strong potential for next-generation AR/MR optical elements. This could enable thinner, lighter devices with fields of view exceeding 70 degrees, setting the stage for SiC to become a key material in future consumer optics.

Collectively, these developments mark that SiC will extend far beyond traditional power electronics, and place an increasingly central role in the thermal management backbone of HPC systems, creating a new S-curve of industry growth.

(Photo credit: Infineon)