Popular Keywords

- About Us

-

Research Report

Research Directory

Semiconductors

LED

Consumer Electronics

Emerging Technologies

- Selected Topics

- Membership

- Price Trends

- Press Center

- News

- Events

- Contact Us

- AI Agent

About TrendForce News

TrendForce News operates independently from our research team, curating key semiconductor and tech updates to support timely, informed decisions.

- Home

- News

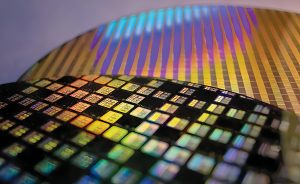

[News] India Fires up 4 Chip Plants, Targets 75% Local Output

Driven by a surge in global market demand, India is aggressively developing its domestic semiconductor capabilities, with plans to commence commercial production later this year.

According to the latest updates from the India Semiconductor Mission, four semiconductor plants are projected to launch commercial operations within the year, following trial production runs that began successively throughout 2025.

Amitesh Kumar Sinha, Joint Secretary at the Ministry of Electronics and Information Technology, noted that the mission has progressed rapidly since its inception in 2022. The initiative has already trained 65,000 professionals, positioning the country to surpass its 10-year target of 85,000 skilled workers well ahead of schedule.

India’s semiconductor strategy encompasses both design and manufacturing. By 2029, the country aims to design and manufacture chips to meet 70% to 75% of domestic demand. Achieving this target will rely heavily on strengthening design capabilities across six core sectors: computing systems, radio frequency (RF), network security, power management, sensors, and memory.

Amid this industry push, Kaynes Semicon has already operationalized its facility in Gujarat, having initiated production in November 2024. Raghu Panicker, the company’s CEO, highlighted that the packaging and testing phase is critical to semiconductor production. He emphasized that this is not merely a matter of physical assembly or casing, but a sophisticated manufacturing process involving 10 to 12 distinct steps.

The expansion of India’s semiconductor ecosystem is underpinned by significant government support. In December 2021, the government announced an outlay of 760 billion rupees (approximately $10 billion) to position India as a global hub for Electronics System Design and Manufacturing (ESDM). This investment cap may be raised further to accommodate the growing demands of artificial intelligence.

These policies have attracted global heavyweights, such as ASML, to establish bases in India, further enhancing local design capabilities and affirming policy stability.

Looking ahead, India aspires to become a global center for semiconductor design by 2035. The roadmap also includes a target to master advanced manufacturing technologies, specifically the mass production of 3-nanometer process chips, by 2032.

This series of strategic moves underscores India’s ambition to secure a pivotal role in the global semiconductor supply chain and lays a solid foundation for future development.

(Photo credit: FREEPIK)