Popular Keywords

- About Us

-

Research Report

Research Directory

Semiconductors

LED

Consumer Electronics

Emerging Technologies

- Selected Topics

- Membership

- Price Trends

- Press Center

- News

- Events

- Contact Us

- AI Agent

About TrendForce News

TrendForce News operates independently from our research team, curating key semiconductor and tech updates to support timely, informed decisions.

- Home

- News

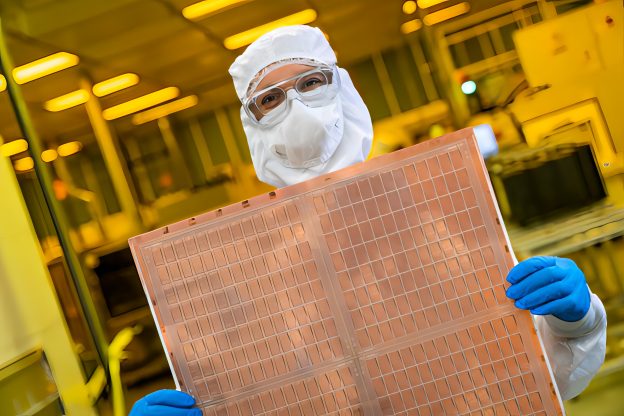

[News] Tesla and Apple Reportedly Eye Glass Substrates, Lifting Prospects for Taiwanese Suppliers

According to Commercial Times, industry sources suggest that Tesla and Apple are evaluating the use of glass substrates to improve chip performance. The report notes that if adopted, the move would likely target advanced, large-die applications such as autonomous driving platforms or AI server processors. However, citing industry sources, the report also adds that while glass substrates are meant to replace silicon interposers, there is not yet a pressing “must-use” need.

Meanwhile, the report indicates that with Apple and Tesla signaling possible adoption, leading Taiwanese substrate makers such as Unimicron and Nanya PCB are stepping up efforts, having reportedly sent samples to customers for testing and received initial feedback.

Industry sources cited by the report note that if end customers share development costs and provide design parameters, Taiwanese makers can conduct small-scale customized trial runs while continuing to build process expertise and reliability validation, laying the foundation for future commercialization.

At present, according to the report, no company has entered stable mass production, with technology maturity, cost structure, and supply chain integration still under validation. Within this landscape, according to an ETNews report from July, Absolics, a subsidiary of SKC, is reportedly ramping up glass substrate production to increase shipments in preparation for full-scale mass production for customers, making it likely to become the first to commercialize the technology.

Glass Substrates: Advantages and Manufacturing Challenges

As for potential advantages, the report notes that as advanced applications such as server modules and silicon photonics chips exceed 120 millimeters, organic materials face growing warpage and signal bottlenecks, making the superior flatness and stability of glass substrates a promising alternative.

Building on this potential, glass substrates are drawing attention for their ability to boost data processing speeds and enhance AI performance. ETNews reports that companies including Intel, AMD, Samsung Electronics, Amazon, and Broadcom are reportedly pushing to adopt the technology.

Yet despite this momentum, Commercial Times points out that compared with ABF substrates, which already have a mature process system, glass substrates are far more difficult to manufacture. They are prone to cracking during drilling, and downstream steps such as build-up layering and solder mask application cannot be directly applied due to material differences.

Read more

- [News] Intel Reportedly Reaffirms Glass Substrate Roadmap, Pilot Line Rumored in 2025

- [News] Samsung Reportedly Weighs Intel Packaging Investment, Glass Substrate Tie-Up to Challenge TSMC

(Photo credit: Intel)